Respirable crystalline silica (RCS) – a guide to reducing risks with real-time monitoring

Reducing the risk of exposure to crystalline silica dust has become a key focus for governments and regulators, as well as safety campaign groups and companies operating in construction, mining and manufacturing.

Being informed about the presence and level of RCS at a location is key to minimising risk to workers, which is why it is vital to be able to monitor air quality in real-time and for each worker.

What is RCS and who is at risk?

Excessive exposure to dusts via inhalation can lead to serious diseases of the respiratory tract. RCS is not the only dust that is a danger to inhale, but it does pose extremely high risk to workers, due to its prevalence in a wide range of industries.

Silica is commonly found in nature as sand. Crystalline silica exists mainly in three forms: quartz (the most common), cristobalite and tridymite. It can be found in many construction materials, as well as natural materials. Cutting, drilling, sanding and chipping of these materials creates clouds of fine dust, which is classified as respirable crystalline silica (RCS). If inhaled, it is extremely hazardous and can cause chronic obstructive pulmonary disease, silicosis – a long-term lung disease – or lung cancer.

Workers in several industries are known to be at high risk, including construction and demolition, quarrying and mining, and manufacturing. Some activities are specifically associated with RCS exposure. These include concrete scabbling, chasing out, drilling and coring, rubble clearance and removal, crushing and screening, cutting, use of breakers, abrasive blasting, and soil movement. Enclosed environments like tunnels create increased risk.

Workers in enclosed areas, such as tunnels, where pollutants may quickly build to dangerous levels, are at higher risk so care needs to be taken to monitor and implement safety measure. Other activities with potential for very high risk include demolition, sandblasting and any work involving the cutting of materials such as concrete.

The regulatory requirements:

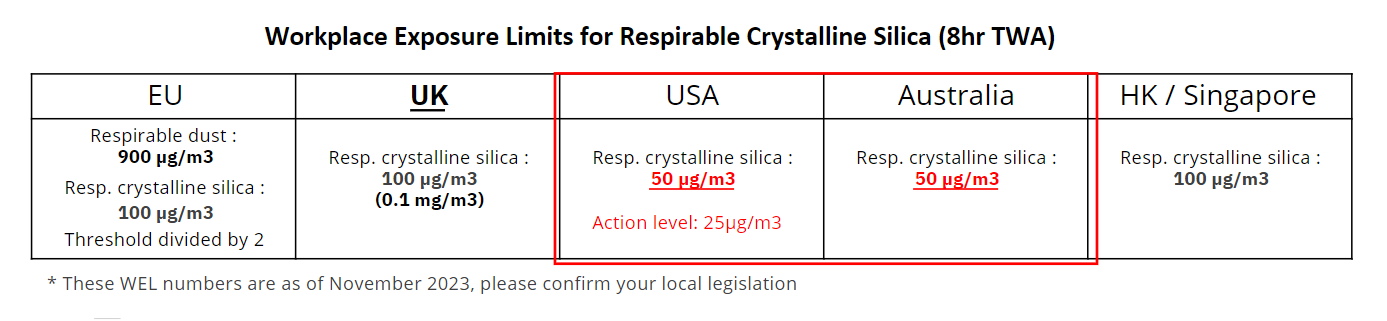

Many countries are passing stricter laws and regulations to limit employee exposure to respirable dust and in particular respirable crystalline silica. In Australia, these include higher fines and a recommendation to prohibit all engineered stone, while in the US there is currently a consultation process around new Mine Safety and Health Administration (MSHA) rules for RCS.

Permissible exposure limits (PEL) or workplace exposure limits / standards (WEL or WES) are the maximum amount of a hazardous substance that can be present in the air, a limit that should not be exceeded. They are a legal requirement. WEL is not the safe limit, any ammount of silica dust exposure can be harmful and exposure must be reduced as low as reasonably practical.

The measurement for a PEL/WEL/WES is averaged over a period of time, known as a time-weighted average (TWA). Two time periods are commonly used: long-term (8 hours) and short-term (15 minutes).

Current best practice:

Internationally, governments and safe-work organisations have put together local best practices in terms of managing RCS. These include WHSQ’s 2022 Code of Practice in Australia, the COSHH Assessment in the UK, guidance from OSHA and state plans in the US and, in Canada, various tools exercised by provinces or territories like Ontario and British Columbia.

These best practices focus on preventing the dust in the first place, suppressing, or extracting dust after it is created, and protecting workers from it, for example, with respiratory personal protection equipment (RPPE). Compliance often includes monitoring requirements such as sampling and laboratory analysis, and health surveillance of workers.

However, questions and limitations remain. Control measures that were assessed and confirmed to be working well may not continue in effectiveness. Equipment may degrade or malfunction. User error may mean preventative measures are not deployed correctly or in the right place. Circumstances may have changed such that the same measure no longer produces the same results. This could include environmental conditions such as weather, properties of new materials now in use, as well as changes in worker behaviour or working methods. Personal protective equipment (PPE) functions well, but only if it is being used, stored, and maintained correctly. Dust rises and moves, impacting other workers than anticipated.

Overall, traditional samples in compliance monitoring confirm the conditions that held true at a particular moment and in the specific location the samples are taken. The cycle of sample followed by laboratory analysis also takes days for results to be available, leaving workers exposed to risk for some time after the sample is taken.

Why smart monitoring is key:

Larger particles that you inhale are filtered out before they reach the lungs. Respirable, as in ‘respirable crystalline silica’, describes particles of 10 microns or smaller that can reach and damage areas of the lungs such as the pulmonary alveolar. This is why it is vital that monitoring is smart, able to identify both the size and type of particle and establish in what proportion it is present.

Exposure limits are set per worker, so it is vital to have data for each individual and personal monitoring guarantees the most accurate information. For example, RCS is often most concentrated near to where the dust is being generated and then can dissipate within a few meters. Monitoring dust from one area of the site only might miss a concentration of exposure in a specific area, whereas individual sensors ensure that personnel can be monitored specifically for their location.

Smart continuous monitoring allows site managers to observe changes and ensure that measures are effective. Exposure characteristics will inevitably evolve over the course of a project as it moves from phase to phase. To properly understand the situation onsite, it is necessary to assess trends, such as RCS increasing within a certain zone. Continuous data makes that much quicker and easier than weekly or fortnightly sampling only.

If concerning trends emerge, managers will want to know why. Perhaps the cause is some new activity. Continuous data lets managers identify the correlation between the timings of this activity and surges in detected RCS. Remedial action can then be taken, such as changing the time, place, or characteristics of the new task, or adding additional control measures.

New control measures must, of course, be followed by an assessment of how much effect they are having. Rapid and full information will allow an understanding of whether the measures are working as planned.

UBY’s AI-enabled solution:

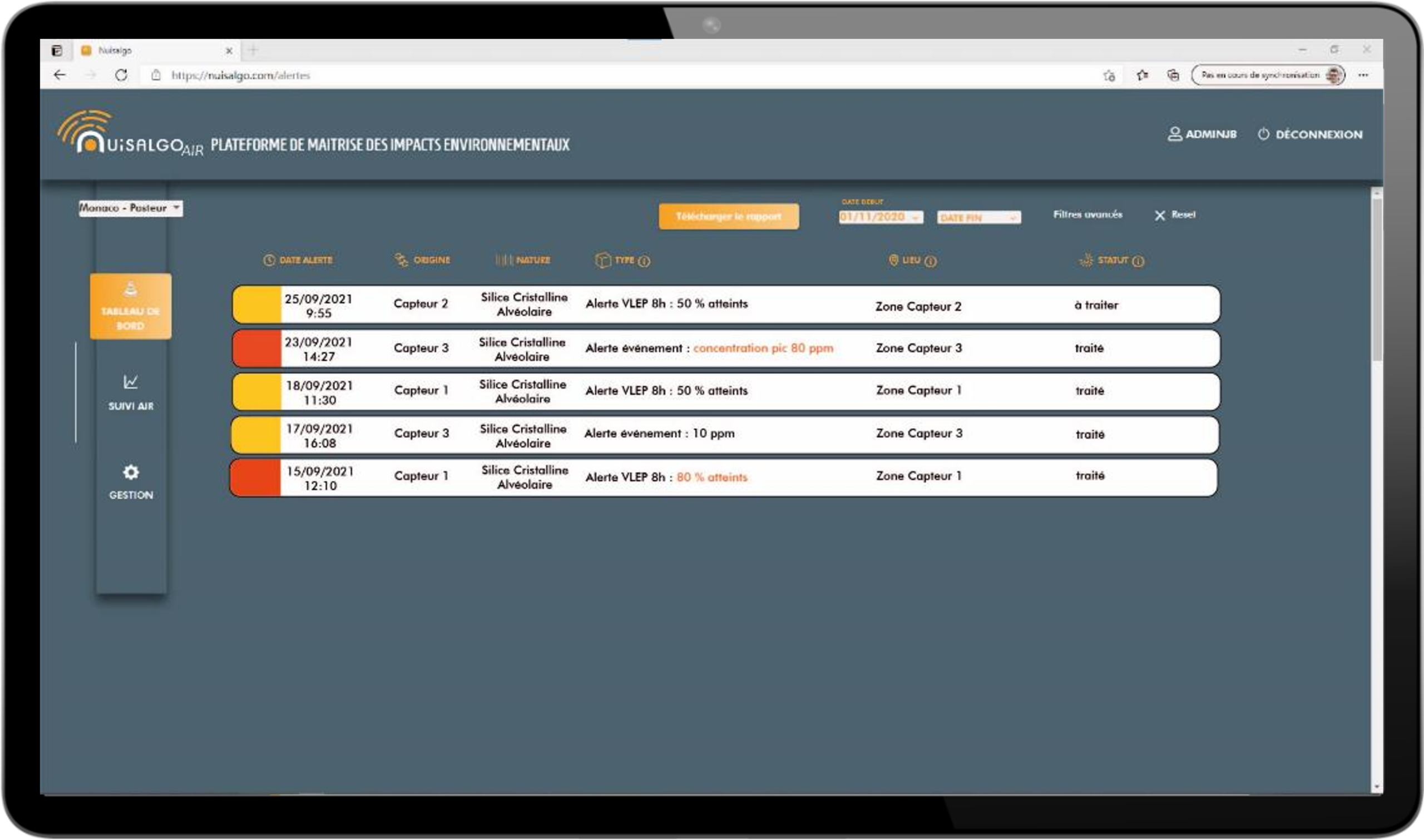

UBY’s uDust is a portable spectrophotometric sensor, worn by workers during the working day, accompanying them throughout the site and providing continuous silica monitoring of the individuals exposure. The system’s 0.3 litre per minute intake replicates the breathing of a person for accurate sample collection. Data is sent directly to the cloud. The results of the patented classification algorithm are then available in real-time to users of our online platform UBY Safe, who can immediately assess what the smart system has measured and identified.

Information is presented visually within our clear and customisable dashboards. Outputs such as graphs show information in relation to short-term threshold event issues, mid-term threshold assessment (i.e., percentage of the WEL period-limit currently reached) and any regulatory threshold issue (WEL limit exceeded). Alerts will be sent automatically in that latter case, ensuring managers will always be able to react effectively and fast.

Data covering the entire project is stored for future analysis. Users can customise and schedule automated reports, and can refer back or create custom reports, if required to demonstrate compliance later. The system can be combined with geolocation tools from the wider UBY Safe soloution, making it easier to manage emergency measures and evacuations.

The benefits of real-time monitoring:

Contractors know they need to keep their people safe, comply with all regulatory requirements, and have tools to prove compliance. UBY’s smart solution will detect, alert, and manage, all in real-time. Rich data on measured particulate levels allow managers to know and demonstrate compliance with workplace exposure limits regulations and verify working methods and protective control measures.

Automated monitoring, reporting and alerting saves time, providing improved management of the regulatory process with less resource drain. Workers and regulators will see the enhanced vigilance and dedication to compliance and safety.

Become a health and safety champion:

To go beyond minimal or reactive compliance, take the lead with state-of-the-art, proprietary technology. Protect workers, company and clients. Demonstrate the highest levels of commitment to workers and be seen as a best-in-class advocate of smarter and better solutions to your regulatory and safety obligations.

f you have a specific project in mind and would like support with specification or advice on local requirements, please contact us.