WORKSITE PRODUCTIVITY

Optimise Costs, Secure Schedules, and Anticipate Risks

Based on data gathered from your equipment, our tool provides you with indicators that are as close as possible to the reality on-field, enabling you to make the right decisions in the shortest possible time.

Control Worksite Progress

To identify deviations from the plan during a project, a mere financial overview is not enough. This information must be cross-referenced with data from the field. Our tool serves as a genuine, personalised cockpit—it provides real-time feedback on your production tools’ activity and a headcount per zone of your workforce.

Examples of real-time machine monitoring: Location (outdoors or indoors); status of the machine (running vs idling); direction of movement.

Since this snapshot follows the on-site situation as closely as possible, you can anticipate if resource deployment is required according to the program’s schedule and ensure that production priorities are respected.

Improve Production Methods

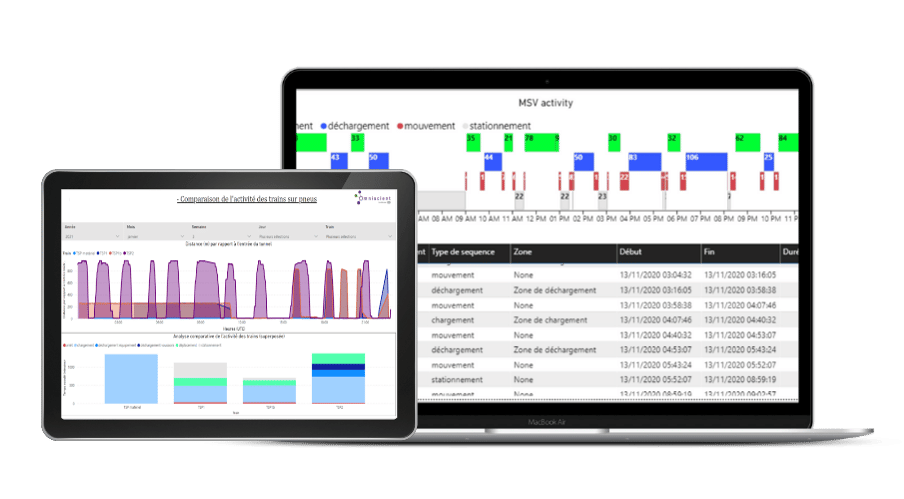

Analysing the production rate of each piece of equipment allows the Method teams to identify friction points more rapidly. From the various indicators provided by our platform, you can collect method vs. time measurements, which can be used to optimise production schedules and costs for subsequent cost estimates.

To ensure that the production rate is maintained, our product provides time analysis measures for each key area of the worksite (e.g. time spent loading/unloading, average speed, number of cycles completed per day).

Save Time in Daily Equipment Stock Management

To address recurring challenges in equipment fleet management such as equipment being scattered throughout the site, lack of traceability, or over-investment, our product allows you to inventory all your equipment with a single application, locate your connected resources in real time, and analyse the general state of your fleet (compliance status, upcoming regulatory controls, dormant stock, and more).

For more information about the fleet management, visit My Omniscient’s website

Platform Features

Inventory per area

Localisation on a map or a worksite plan

Monitoring of regulatory controls

Alert system

Management of equipment conditions

Real-time status of machinery

Dashboards

Benefits of this solution

Anticipate material and human resource requirements

Save time in reporting thanks to a fact-based view of the activity

React in a timely manner in case of deviations

Optimise your organisation and methods

Our references

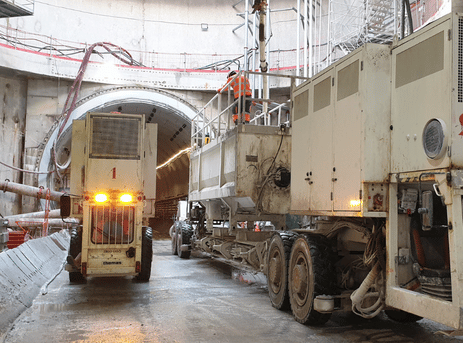

Horizon Grand Paris: Line 15 South – T3A Tunnel

Monitoring of multi-service vehicles in the Line 15 South tunnel

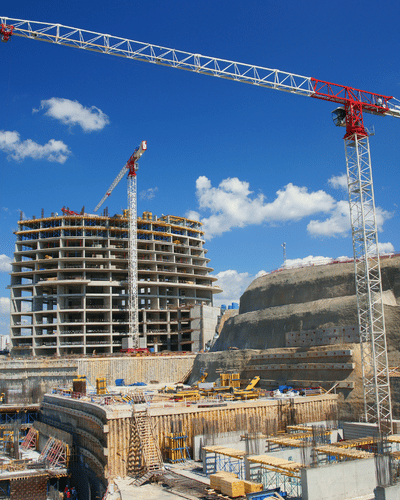

Dragages Singapore: Glory Tower – Singapore

Production and workforce monitoring in a 51-floor tower

Bouygues Travaux Publics: Extension of LRT1 light rail line

Monitoring the activity of precast bridge span transporters for the construction of a 6.6km viaduct

Want to learn more ?

Whether you want to ask a question about our products or simply exchange on the subject, do not hesitate to get in touch with our teams