Air quality monitoring and worker geolocation to ensure safety during the Lille-Europe station renovation project

The Project

UBY was contracted by Colas Rail to provide a smart environmental monitoring and geolocation solution to help ensure a safe environment for all workers at all times during the Lille-Europe station renovation project.

Summary

Client : SNCF

Contractor: Colas Rail

Project type: Public works; Rail

Project completion: 2023

UBY solutions used: UBY Safe

Site Overview

Lille-Europe TGV (high-speed rail) station came into service in 1994 and is now undergoing rail and ballast renovation works, including the replacement of rail expansion devices.

Due to its strategic position as a rail hub serving major French cities – including Paris, Lyon and Marseille – and European rail services (Eurostar and Thalys), the work needed to be carried out overnight and in a contained area.

The Challenge

The project’s main concern was worker safety for the 80 staff on site.

In addition to the risks on a site of this kind, such as ballast activities, undercutting and adjustment, there were further risks relating to prolonged exposure to dust, gas and other harmful substances.

UBY was tasked with delivering two main objectives. Firstly, alerting the client to any cases of worker overexposure to harmful particulates that pose a danger to health. And, secondly, deploying an additional safety device to enable all workers in and around the tunnels and traffic areas to be located in the event of accidents, fire alerts or any other incidents requiring evacuation.

UBY Solution

Ensuring the safety of 80 individuals on site involved a range of solutions, including monitoring environmental pollutants, verifying the proper placement of safety equipment, and geolocation of the workforce to ensure full compliance with health and safety protocols.

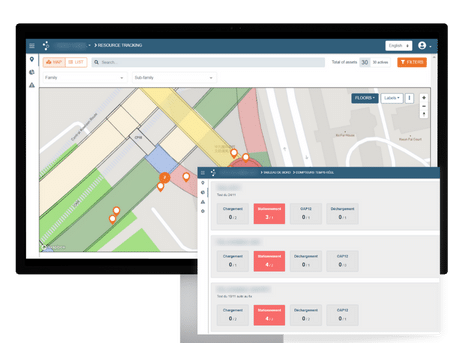

The instrumentation used included 3 air quality sensors, 96 anchors, 300 chips and a MESH network, providing geolocation information accurate to 5m – taking count every 2 minutes per zone and company – as well as monitoring particulates including O2, H2S, CO, NO2, SO2, CO2, PM and COV.

All information collected was stored and visualised in our online platform, allowing the client to promptly check – in real time – worker location and headcount, intrusion alerts for dangerous or restricted areas and dust levels (with pre-emptive alerts set for threshold levels). This allowed the client to identify any potential issues and proactively implement appropriate protective measures before they became problematic.

Looking to minimise risk and protect workers on your next project? Get in touch today.

Related case studies:

Fécamp Offshore Wind Farm: Structural health monitoring for EDF

UBY state-of-the-art sensors provide long term condition monitoring in challenging marine environment

Pawtucket Tunnel project: UBY helps ensure a trouble-free experience for residents

Sound and vibration monitoring and software to support better communication with nearby residents.

Bouygues Travaux Publics: Lock of Méricourt

Monitoring and control of the impacts of the construction site on water quality

Want to learn more ?

Whether you want to ask a question about our products or simply exchange on the subject, do not hesitate to get in touch with our teams